SGT Pipe Reducing Machine is a special equipment for HDPE pipe lining to repair underground pipes. It is by reducing the diameter of the HDPE pipe to be lined into the old pipe, the line is compressed into a u-shaped shape and tied with tape to fix it, then it is pulled into the downpipe by the traction equipment, and then the technology of expanding pipe is used for restoration, finally forming the pipe in the pipe, achieving the purpose of repairing the pipe lining.

Suitable for butt welding of plastic pipes and fittings made of PE, PP and PVDF in a ditch in worksite or workshop. Consists of basic frame, hydraulic unit, planing tool, separate heating plate, support for planing tool & heating plate, and optional parts. Removable PTFE coated heating plate with high accurate temperature control system. Electric planning tool with safety limit switch enables to start it only when it is locked in operation position. Made of lightweight and high strength material. Low starting pressure and high reliable seal structure. Changeable welding position brings more convenience while welding various fittings. Separate two-channel timer records times in soaking and cooling phases. High-accurate and shockproof pressure meter indicates clearer readings. Labor saving and high efficient crane is available to lift planing tool and heating plate .

Electric hoist winch for lifting and pulling. fix speed and variable speed by variable frequency as option.The winch is mainly applied to lifting, pulling and loading or unloading the weight. For example, it can be used to mount and dismount large and medium-sized concrete and steel structure and machinery equipment. Also, it could be utilized as the lifting mechanism of hoisting machinery. This product features orderly-arranged steel wire ropes, safe slinging, smooth transmission and convenient maintenance. This product can be used for the equipment installation in bridge building, port construction, wharf construction, shipyard building and other large-scale factories and mines project.

Fast heating,high thermal efficiency,high controllability; Easy maintenance&operation; High quality component; Self-protect function

High quality components,advanced control system,stable operation; Modular design,single switch control,convenient maintenance and use; The equipment is small in size,easy to carry,more suitable for field construction; Fast heating,high thermal efficiency,good controllablitity; Focus on safety design,self protection function is reliable,to ensure the safe operation of equipment,to strengthen the safety of construction personnel protection.

Easy installation&operation; Fast clamping,high precision; Compact size; Wide application.

Compact structure,stable performance,easy operation; High precision,wide application; Limiting device in the supporting system; Quick adjustment,easy maintenance

High hoisting capacity; Simple transmission,reliable performance,low energy consumption,free maintenance; Low vibration,low noise; Operating weight:9625kg/9695kg; Overall dimensions:5415*2370*2955mm

Wheel type tractor chassis,high speed,convenient transportation; Severe operating environment such as swamp,desert,soft soil and so on; Waterproofing treatment for high/low voltage apparatus; Front/back enhanced towing hook; Stable operation,low noise,long operating life,easy maintenance.

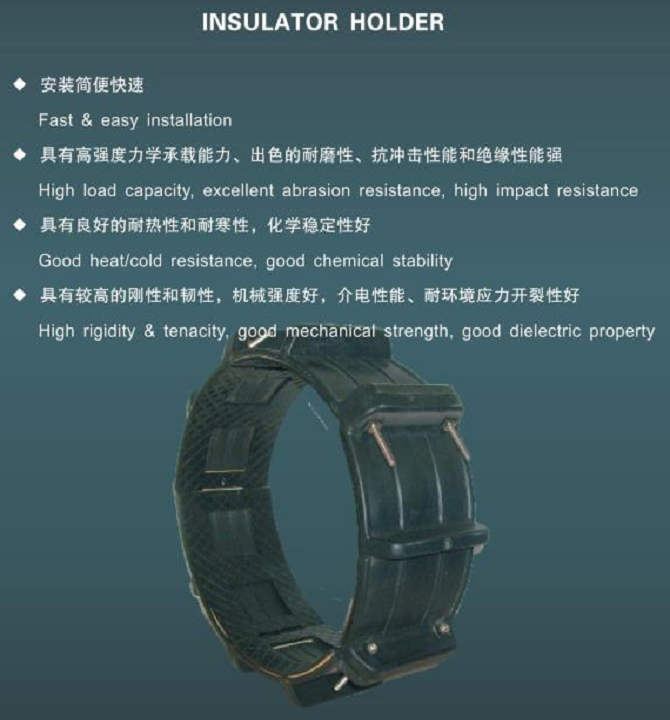

Fast&easy installation; High load capacity,excellent abrasion resistance,high impact resistance; Good heat/cold resistance,good chemical stability; High rigidity&tenacity,good mechanical strength,good dielectric property

Easy installation&operation Fast&well-distributed heating wide application

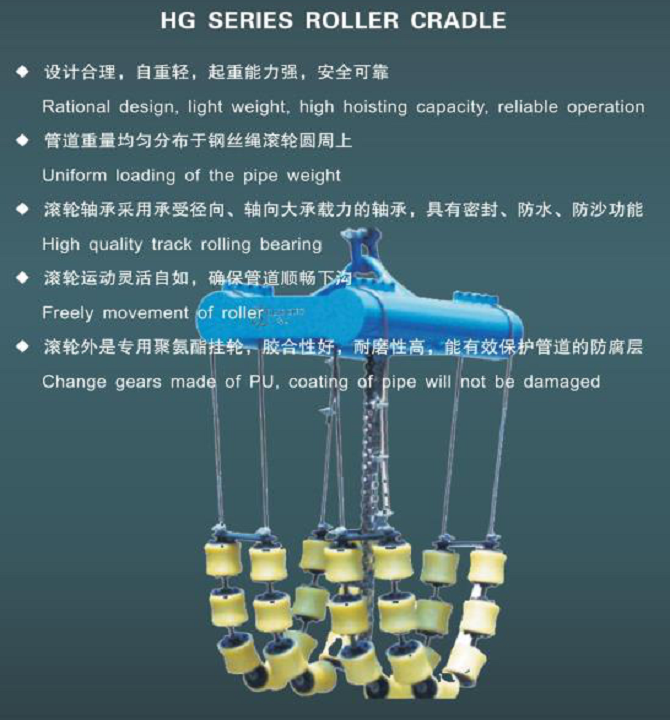

Rational design,light weight,high hoisting capacity,reliable operation. Uniform loading of the pipe weight. High quality track rolling bearing. Freely movement of roller. Change gears made of PU,coating of pipe will not be damaged.

Maxinum hoisting capacity:90t Longer boom Engine:CUMMINS NT855-C360 Operating weight:55t Transport dimension of machine:5630*3436*3540mm

Maxinum hoisting capacity:70t Longer boom Engine:CUMMINS NT855-C360 Operating weight:49t Transport dimension of machine:5630*3400*3540mm

Maxinum hoisting capacity:45t Longer boom Engine:CUMMINS NT855-C280 Operating weight:35t Transport dimension of machine:4855*3384*3270mm

Maxinum hoisting capacity:25t Longer boom Engine:SHANGCHAI SC11CB Operating weight:22t Transport dimension of machine:4150*3050*3250mm

All positon automatic pipeline welding machine 1.Suitable pipe: more than 130mm 2.Pipe wall thickness: 4-50mm 3.Suitable for : C.S,S.S,A.S, Low temperature steel(S.S is with special rail) 4.Suitable seam welding: pipe to pipe,pipe to elbow, pipe to flange 5.Drive system; stepping motor wheels and Gear/worm transferring 6.Control mode: Button to add and subtract speed 7.Adjustment manner: electrical circuitry control 8.Oscillating system: the company's proprietary technology products, / swing stepper motor 9.Control system: the company's proprietary technology products, the digital control

Easy to use,easy to mantain. Rapid temperature increase. High-temperature corrosion resistant. Safe and reliable.