Main structure and work principle

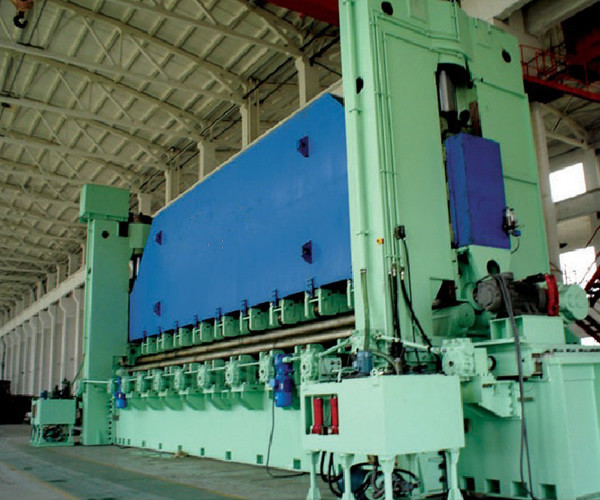

A.This machine is symmetrical rolling machine, down up roller and then let up and down roller doopposite roll to bend steel plate.

B. This machine composed of two parts those are working part welded in whole chassis and moving part. Working part composed of left and right bearing base, one up roller, two bottom rollers (the material of the three rollers is 45#steel and do heat treatment), lifting screw and turbine and other accessory parts. Down rollers drive up roller to move, up roller can do up and down move by height way. Drive part composed of main motor, main speed reducer and other accessory parts.

C. Bottom rollers were drove by main motor through main speed reducer, output spindle of main speed reducer driven to two down rollers by one group gears, the revolve direction of rollers adjusted by main motor.

D. Upper roll lifted by accessory motor through vice speed reducer drive worm and worm wheel mechanism of right/left rolls bearing base. That to let the lifting pole do up and down move.

E. Unloading device is designed to remove the workpiece after drums bended into shape. Before unloading the upper rolls move to up limit position, the balance device on upper rolls ends hit upper rolls, draw out the spindle of the pin, then to remove the workpiece.

Model | Max.plate thickness(mm) | Plate width(mm) | Main motor power |

W11NC-20*8000 | 20 | 8000 | 45 |

W11NC-25*12000 | 25 | 12000 | 55 |

W11NC-30*12000 | 30 | 12000 | 75 |

W11NC-30*16000 | 30 | 16000 | 110 |

W11NC-40*18000 | 40 | 18000 | 2*75 |

W11NC-40*21000 | 40 | 21000 | 2*75 |

Related products