1. Introduction

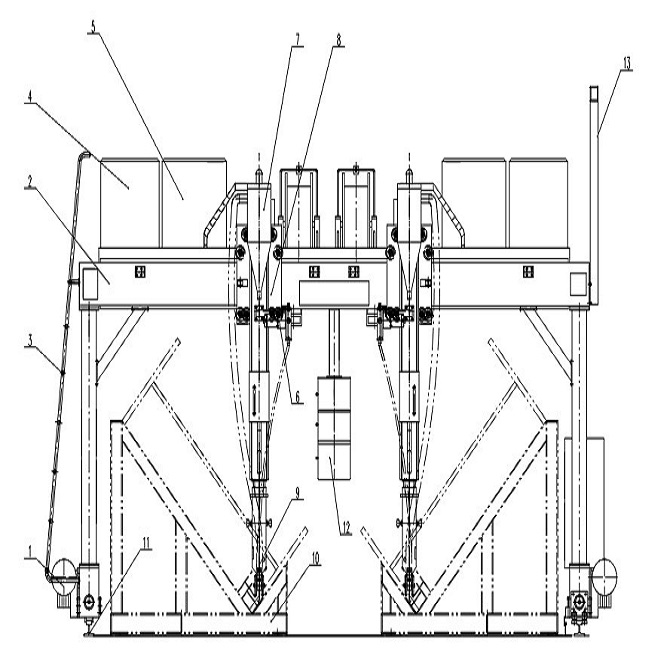

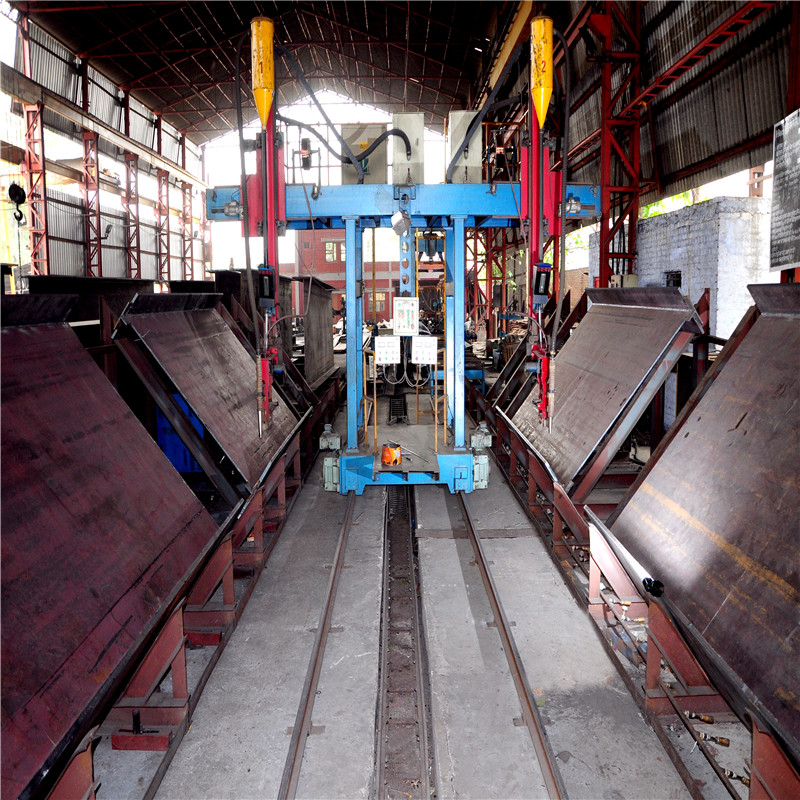

After finished the H-beam assembling process, H-beam automatic SAW welding is required. It has several structural styles: LHA gantry type, LHT double cantilever type and LHC cantilever type. It adopts A.C. variable frequency control to realize back and forth welding. It has stable and reliable working and simple and convenient operation. Special designed arc-guiding rack can satisfy the welding requirements of small H-beam and star/cross beam.

2. Main Parameters

Model | LHA | |||||

Rail span (mm) | 4000 | 5000 | 5500 | |||

Controller position | Middle | Side | Middle | Side | Middle | Side |

Web height (mm) | 160-1200 | 160-1500 | 160-2000 | 160-2300 | 160-2200 | 160--2500 |

Flange width(mm) | 140-800 | |||||

Job length (mm) | 4000-15000 | |||||

Welding speed (mm/min) | 240-2400 | |||||

Machine power (KW) | 9 | 9.7 | ||||

Power supply | AC380V, 50HZ, 3P or tailor made | |||||

Above are our standard models and parameters, and it can be designed and manufactured on request. | ||||||

*We reserve the right to alter specifications without prior notice.

3. Main features

The standard models of our gantry type H-beam automatic welding machine have the following features:

1.Two welding heads can weld two H-beams at the same time;

2.Controller can be placed in the middle of gantry or at both sides of the gantry;

3.Robust all steel fabrication with stable structure and good rigidity, and no

deformation after long time using;

4.A.C. variable frequency control;

5.Back and forth welding to improve the efficiency;

6.With American Lincoln DC-1000,NA-3S SAW welding system or Chinese famous brand;

7.With flux feeding and recovery machine;

8.It can weld star/cross beam by changing the arc-guiding device;

9. Heat treatment to main welding parts after welding; sand blasting treatment to main welding parts before painting;

10.All motion parts have lubrication system;

11.Main electric elements are ABB/Siemens brands;

12. Lifting lug;

Related products